The pick and place machine is a kind of automatic assembly machine that picks up components from the feeder or tray using a vacuum, then scans the components and rotates the components to the right angle before mounting them onto the printed circuit boards.

Before the real SMT production, it may take a few minutes or hours to make the correct setup, but once the production programs are ready, then the pick and place machine can work fast and accurately.

Firstly, the pick and place machine gets the printed circuit boards into a certain mounting position from the conveyor system.

Then, the head camera of the pick and place machine will perform to scan the fiducial marks of the PCB to confirm the exact location and coordinates of the printed circuit PCB inside the machine.

Generally, the fiducial marks are 2 to 4 special points that are normally at the corners of the substrate.

Next, the machine will begin to mount the components onto the printed circuit boards according to the software optimization result.

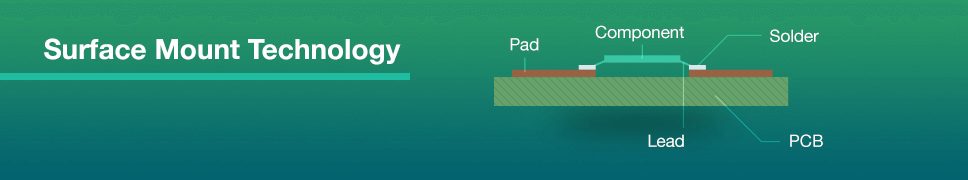

SMT Technology

Generally, optimization is the most complicated process of a pick and place machine, which is the essential factor to decide the machine efficiency and accuracy.

If there are numerous electronic components with various shapes and sizes that have to be placed on the specific locations of the printed circuit boards, then you will find how to make an efficient assembly operation is complex and time-consuming.

Usually, the placement head, feeder carrier, and the PCB platform all move independently at different speeds. Actually, the placement speed will change according to the various sizes of the components.

By principle, smaller size components are always be mounted before the larger sized chips, for the reason that the mounted larger sized components on the surface of the boards may be shifted when the placement head increases the speed to pick and place the smaller sized components.

Because the placement head, feeder carrier, and the PCB platform move simultaneously, in order to increase the total machine output, we should take all the three-movement delays into consideration.

Finally, once completed (or partially completed, e.g. due to component run out or job completion), the PCB is moved out from the SMD placement machine

Keywords:

SMT Production Line Chm, SMT Line LED Display, Air PurifICation For Reflow Oven, Desktop Selecting Wave Soldering Machine, PICk And Place Machine With 8 Heads 66 Feeders, AutomatIC PICk And Place Machine For Pvc Foam Board, SMD PICk And Place Reflow Oven Machine Stencil Printer, SMT PICk And Place Machineder, Placement Machine, THT PICk And Placement Machine, UltrasonIC Cleaner PCB Generator, PCB Industrial UltrasonIC Cleaner, PCB Board Cleaner Crown, Vacuum Cleaner PCB Designer