One of the most costly and time-consuming processes of electronics assembly is programming the printed circuit board.

Before starting each new production, initially, here are three steps: set up the components and feeders, acquire the correct printed circuit board data, recognize components and specify their corresponding location on the PCB, the last is the program optimization.

Please check the detailed introduction of these four steps in the following content.

6.1 Components and feeders set up

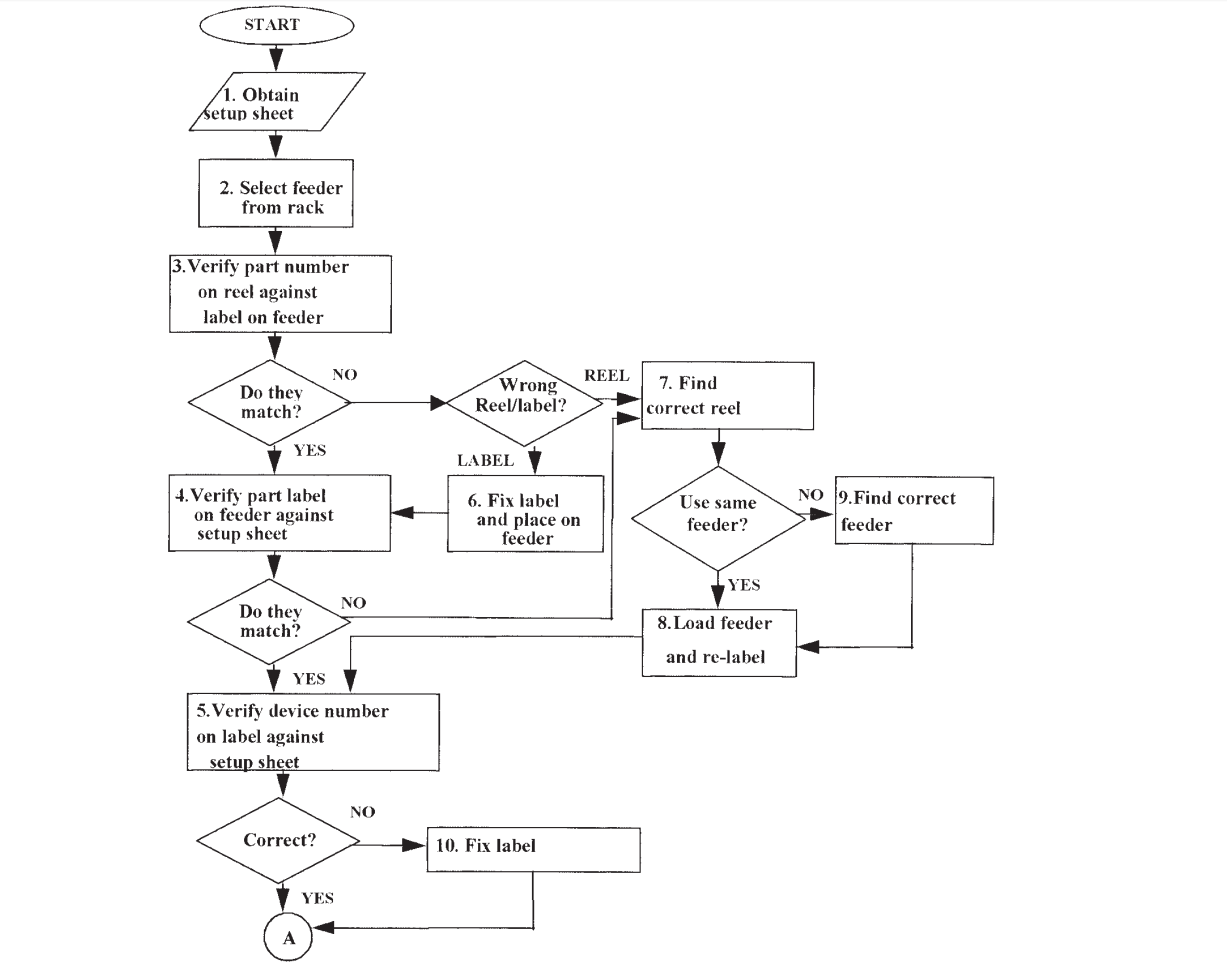

Figure 1-Components and feeders set up

Procedure in figure 1:

Firstly, the operator should acquire the setup sheet that including the PCB and chip information required.

Then according to the setup sheet, he can select the suitable feeders from the feeder rack, and exam whether the components from the feeder are right, and exam whether the size of the feeder is correct, as well as check whether the feeder is the right type for the present machine.

last but not least, the operator should also check the device position for the component is right or not. Then, according to the allocation of the pick and place machine, the operator can put the feeders at corresponding locations on the feeder banks.

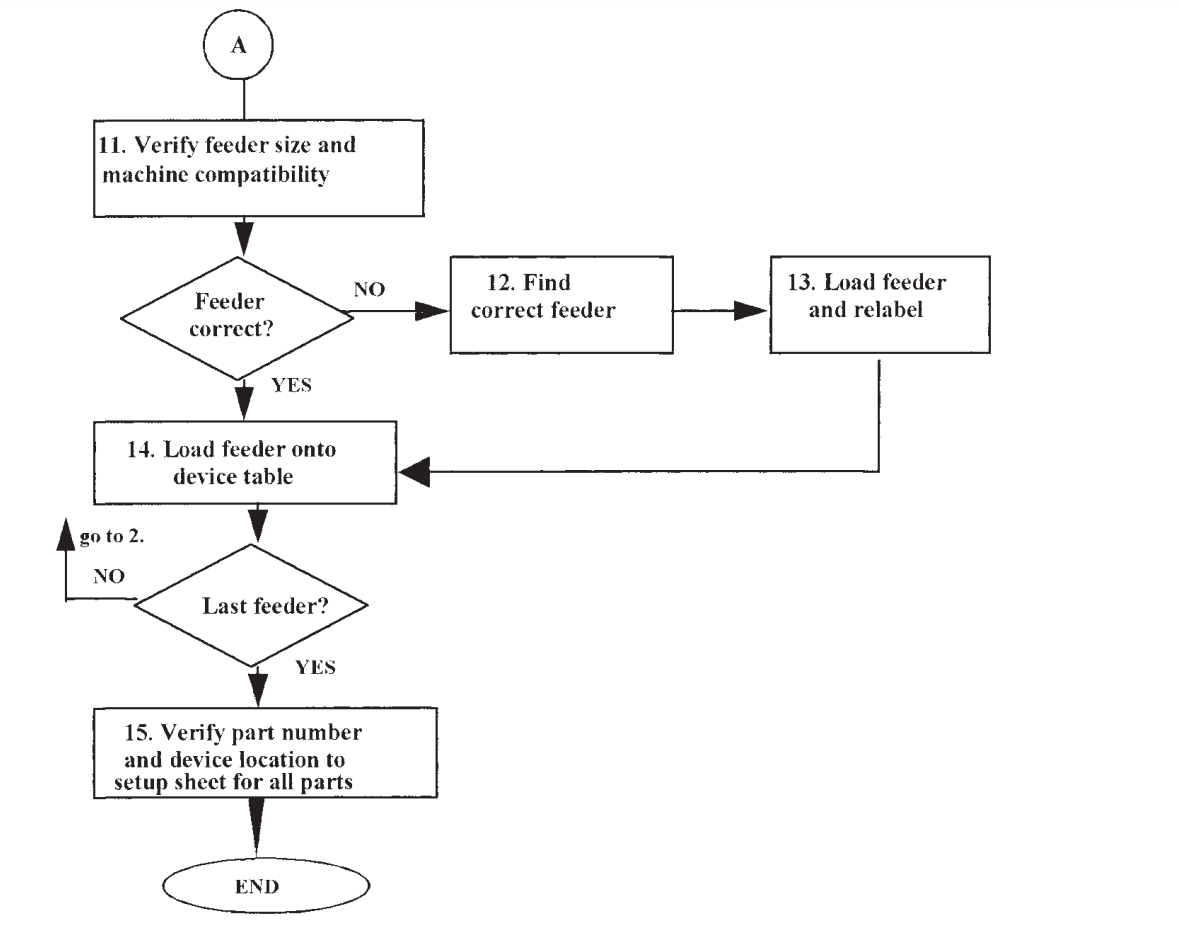

Procedure in figure 2:

Figure 2

The operator can go back to figure 2 to do this step again until all feeders are placed on the feeder banks. After loading all the feeders, we should check again to make sure that every component has been placed in the correct feeder locations on the pick and place machine.

These two hard parts for the setup were the quantity of various components, and hence the number of feeders, required by the particular printed circuit boards.

Whereupon, the procedure of setup is a function of board complexity. This kind of situation is aggravated by the total complication of the factory, which increases the demanded effort to keep track of all the factors of the setups such as feeders, racks, and reels.

- Brief Summary:

This step will take up about 50% of the whole setup time for the pick and place machine.

Usually, in order to finish this verification process faster, we always have to operators at the same time. One of them read the part number and its feeder location, and the other check the numbers according to the setup sheet.

For instance, if there are 50 feeders that we are going to set up, which will take an approximate half-hour. For the reason that the errors are costly, the setup examine is must be performed to ensure that the setup is right.

If the automatic vision system does not detect the error when the component is placed wrong, then all the boards will be mounted with the wrong parts. Eventually, there will be a huge waste of both material and labor.

Generally, this kind of error is hard to be found until the boards are being tested after the placement, then we should spend a lot of time reworking all the boards with the wrong placement.

Hence, instead of spending a long time reworking, it is better to verify and re-verify the components and feeders set up before the real production.

Keywords:

GraphICs Card SMT Production SMT Line, SMT Plugin Line, Lead-Free Reflow Oven, DIP Wave Solder Machine, PICk N Place Machine, PICk And Place Machine Cost, SMT Screen Printer, Yamaha PICk And Place, SMT Mounter, PICk And Place, SMT Machine, , Cleaning Machine SMT LED, SMT / PCB / LED No-Clean Soldering Paste, PCB Surface Cleaning Machine, PCB Board Cleaning Machine, UltrasonIC PCB Cleaning Machine, Screw Tighten Tool Screw Tighten Robot, Robot Screws, Locking Screw Robot, Screw Type Robot, Axis Robot Screw, Manual Screw Tightening Robot